SuperBungalows, a New Cross-Laminated Timber Apartment Building, is a Los Angeles First

Photo © Madeline Tolle

The SuperBungalows, a new apartment building completed this spring in the hip Silver Lake neighborhood of Los Angeles, is not a traditional bungalow. The project is an answer to LA’s need for density and housing, with a nod to the pleasures of living in an individual residence with a porch. It replaced an existing single-family house, an increasingly common occurrence in a city where land values make houses unaffordable to all but the rich or lucky familial inheritors. Most notably, the SuperBungalows represents the first cross-laminated timber (CLT) multifamily residential building in Los Angeles, the start of what the developer SuperLA hopes to replicate many times in the city.

Photo © Madeline Tolle

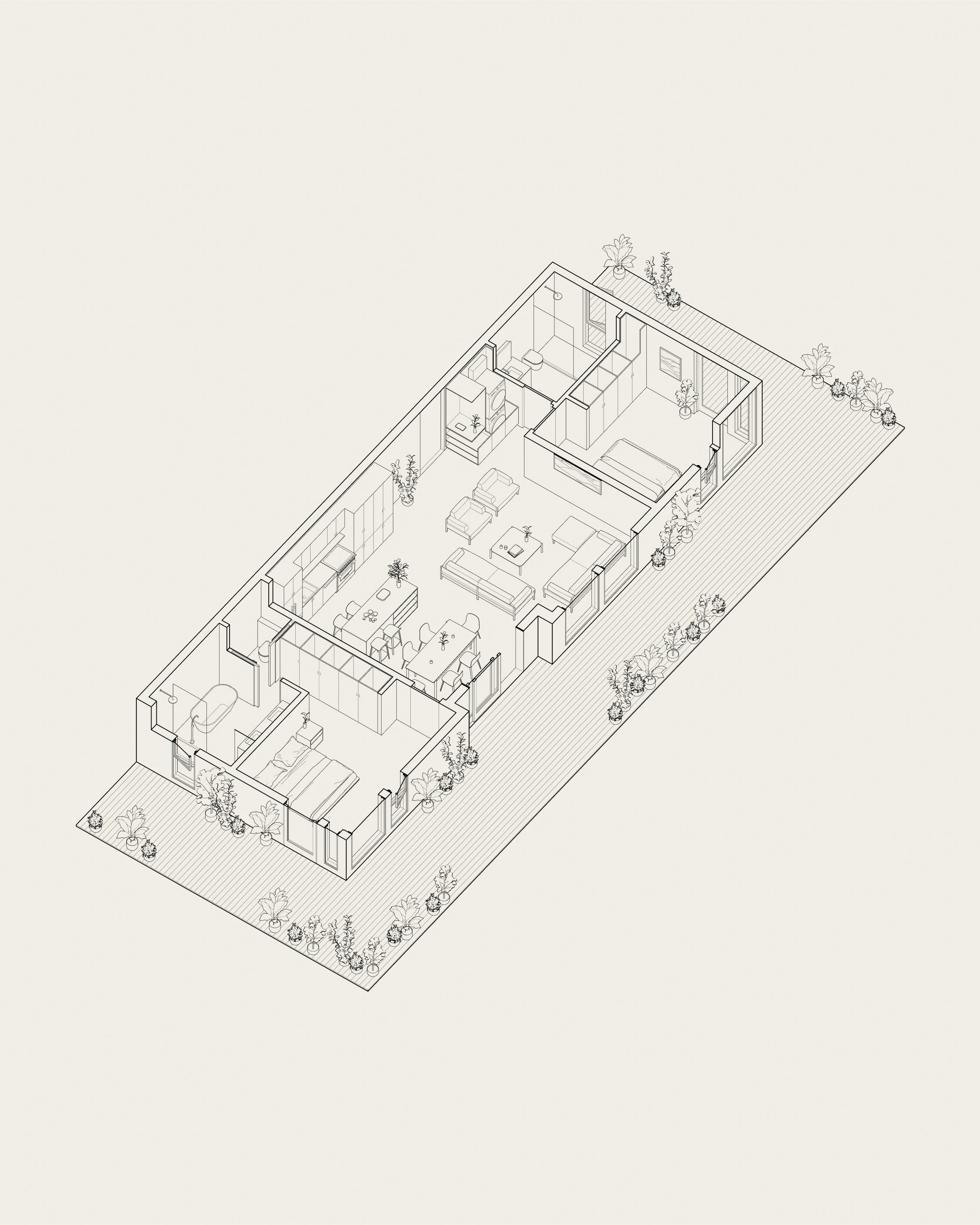

Consisting of nine units, six one-bedrooms and three two-bedrooms, there are no party walls for the market-rate apartments. Each unit is set apart by private balconies and shared outdoor spaces like a small bungalow—the difference being the one-bedroom units are stacked in threes at either end of the east-west-oriented rectangular building, while the two-bedroom units stack to form the middle. Outdoor corridors and open stairs, along with an elevator, define the south elevation, while the entire mass sits on a concrete foundation and parking garage that takes advantage of the sloping lot to appear unobtrusive given its size. Every square inch of the site is given to something, including the rooftop, which includes a garden, seating, and a photovoltaic array that powers the common spaces.

Photos © Madeline Tolle

Although many apartment buildings in LA feature kitschy names—Cedar Tropics or La Traviata, for example—the SuperBungalows is more of a brand eco-system by SuperLA, a start-up created by Aaron van Schaik. The company’s model includes all aspects of the multifamily market, from land acquisition to design and construction and ongoing ownership and management. The focus on CLT construction, however, is at the heart of the enterprise.

Image courtesy SuperLA

“The way we supply housing now is incredibly inefficient,” says van Schaik, who breaks down SuperLA’s approach into three categories—productization, panelization, and optimization—that he believes addresses the time-consuming ground-up, balloon-framing approach to most multifamily housing projects. First, SuperLA’s in-house designer, Jeff Chinn, planned two standard layouts, which they dub 1-bedroom and 2-bedroom products. A one-bedroom product is always 24 feet wide by 30 feet long, a predictable module that everything is rigorously standardized around to eliminate construction waste and offer a 650-square-foot residence. SuperBungalows was a prototype, but now each product can be easily site adapted to new projects. The company also plans to obtain pre-approval of the products with the City to expedite permitting in the future.

The second category focused on the CLT panels, which were produced by Nordic Structures in Canada out of black spruce. By panelizing the floors and roof with 5-ply, 7-inch-thick CLT, the project minimized on-site construction time. The floors include several layers to address sound transmission requirements, including 2 ½ inches of lightweight concrete and floating Capri cork floor planks. The exterior envelope is a rainscreen finished with CERACLAD panels, a GFRC product with nearly 50 percent recycled content and full recyclability at end of life. The walls were framed more conventionally on site as part of the proof of concept. Van Schaik hopes in the next iteration of the project, the company can panelize the walls and prefabricate them in a facility they are currently developing, or even subcontract them out to other parties.

The CLT panels also reflect a biophilic design sensibility that informs many features of the building, including the cork floors, generously-sized operable windows for cross-ventilation, daylighting and views in the open living room, kitchen, and bedrooms. Van Schaik considers the restrained and natural material palette, daylighting, and expansive use of built-in cabinets and closets to be a more common-sense approach to luxury compared to the granite counter tops and acres of clubby amenities that currently define the top end of the rental market.

Photos © Madeline Tolle

Other features speak to the city’s environmental agenda, including the rainwater storage tanks holding 2,500 gallons for irrigation, secure bicycle storage, and electric vehicle chargers at each parking spot. The building is fully electric, with heat pumps for both hot water and the mechanical system. The landscape design, by Stephen Blewett with CRAFT Landscape Architecture, highlights native species like penstemon, manzanita, and Island Oak and Western Redbud trees.

Optimizing the team and delivery of projects is SuperLA’s third strategic focus, which is one of the reasons the SuperBungalows were able to go from idea to fully-occupied building in less than four years. The SuperLA team is only four people, including project manager Sophia Smith and brand leader Quinn Arneson, but they have also made strategic partnerships with suppliers like Pella windows and Mosa tiles to further expedite production.

Photos © Madeline Tolle

With lessons learned from SuperBungalows for how to get through planning approvals with the city, such as the ability to eliminate adding a layer of plywood over the CLT floor panels, SuperLA is in construction on another, larger building in the neighborhood. Van Schaik says they were able to compress their design time to a month versus a year, plan review to 6 months versus a year, and construction to 14 months instead of two years, which significantly improves the financial return given the apartments will start renting sooner. The new project also includes two units of affordable housing and a transit-oriented communities density bonus, mutually beneficial to both SuperLA and for addressing the city’s perpetual housing crisis.