The Danube River flows from Germany’s Black Forest some 1,800 miles across Europe before pouring into the Black Sea. As the continent’s second-longest river, it has served as a west-to-east conduit, giving rise to the many cities that line its banks, like Vienna, Budapest, and, in north-central Austria, the provincial capital of Linz. There, the Danube Valley Bridge, completed in October 2024 and designed by Stuttgart, Germany–based engineer Schlaich Bergermann Partner (SBP), spans it—the longest earth-anchored suspension bridge in the world.

The project began in 2003 with a design competition that called for a pylon-free bridge to reach over this bend of the river. It connects two segments of the first completed phase of the A26 Linz motorway—they are tunneled through two mountainsides that are designated nature preserves—above existing highways and trunk lines flanking both riverbanks. The company led the winning bid alongside architecture firm Gerkan, Marg & Partners, based in Hamburg, and Innsbruck, Austria–based civil engineer Baumann + Obholzer Ingenieure. Rather than opting for a more traditional arched structure, the design team proposed a nearly 1,000-foot-long suspension bridge, fully anchored within the abutting rocky slopes, with a composite structure of prefabricated steel and concrete supporting it.

The concrete deck was poured atop prefabricated steel and concrete. Photo © Mathias Widmayer, click to enlarge.

“The construction of a huge arch bridge would have been exceedingly difficult in this setting,” notes SBP director Mathias Widmayer. “Our initial proposal consisted of two independent suspension bridges, for each direction of traffic, but we ultimately decided on using two anchorage points rather than four, and a single wide-deck bridge, as a more elegant solution that is also less disruptive to the context.”

Work began in 2019 with the setting of anchor blocks on the north and south faces of the mountainsides. That process entailed the erection of temporary rockfall-protection walls, and the blasting and excavation of construction pits to make room for hundreds of grouted anchors, some over 200 feet in length, and their encasement within 785 cubic yards of reinforced concrete. The installation of the main suspension-cable bundles began at the end of 2021; they comprise 12 parallel spiral cables, each nearly 6 inches in diameter and over 1,600 feet in length. Next came the hanger cables and clamps, spaced approximately 80 feet apart for the undergirding to come.

The suspension cables are anchored at two points. Photo © ASFINAG

These prefabricated steel box and cross girders supporting the deck slab were produced in northern Italy by manufacturer and contractor Maeg Costruzioni and delivered 10 miles from the site as halved, road-transportation-size pieces, then reassembled to become nine segments. Each, at 80 feet wide, weighs up to 350 tons; they measure nearly 7 feet high under the bridge center but graduate in height to 3 feet at the bridge’s ends. Each was designed with temporary connections, “which allowed us to perform a stress-free trial assembly off-site,” adds Widmayer. “That process ensured a smooth installation of the prefabricated components and prevented a number of headaches down the line.”

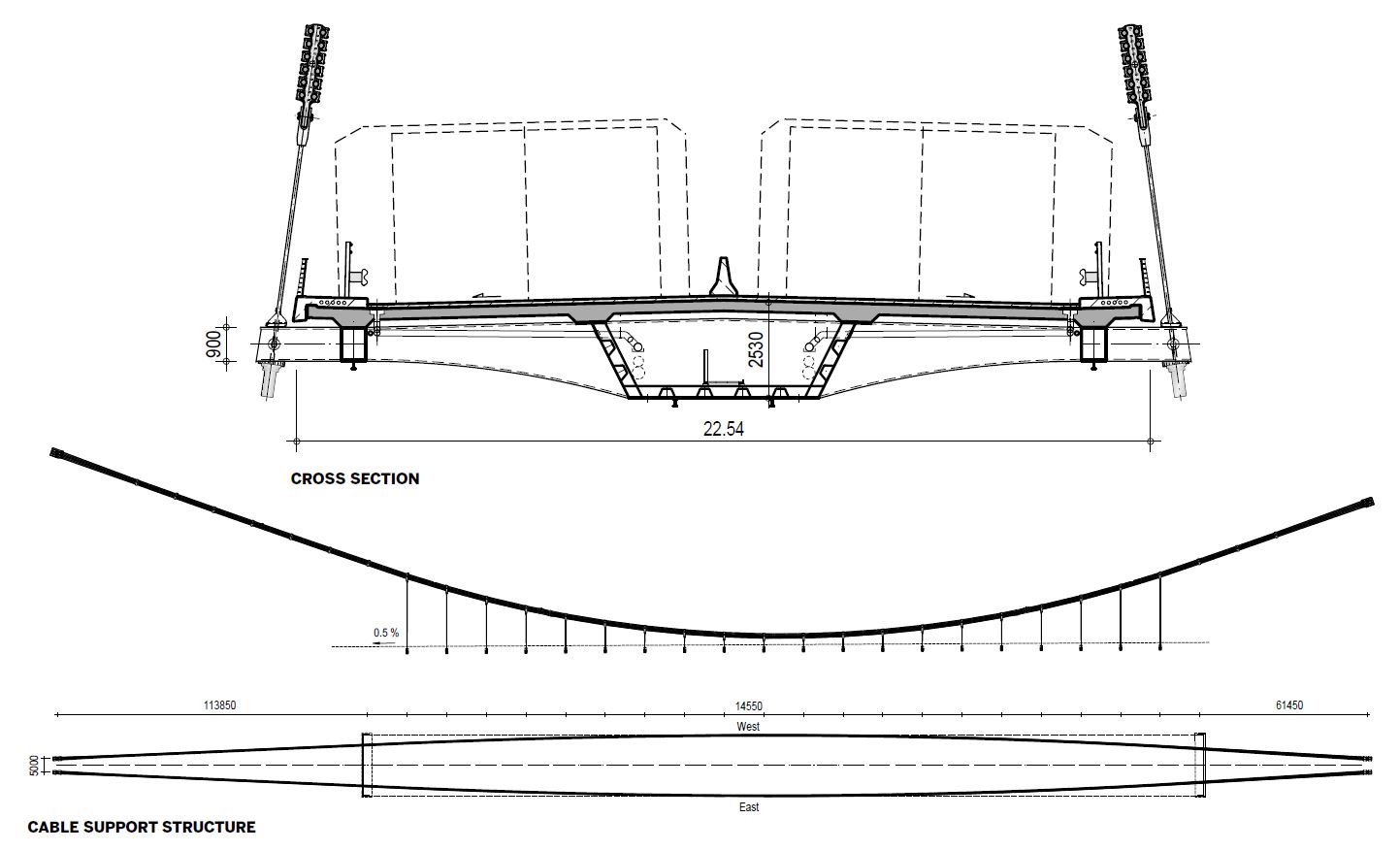

The cable support system was designed to make the bridge column-free. Photo © Conné Van D’Grachten

Click diagram to enlarge

Two of the nine segments abutting the tunnels were set in place during the cable-installation process, with protective framework shielding the traffic flow below from any disruptions. The remaining seven segments, beginning in the middle, were transported by river on a stilt pontoon, that, once in place, could grasp the riverbed with its hydraulic legs to mitigate the Danube’s high velocity as the pieces were craned into position, pinned to the cable structure, and bolted together. The segments, following review of their spacing and alignment, were then welded.

In fall 2022, work began on the placement of semi-finished, 3-inch-thick precast-concrete slabs, which were lifted and placed atop the steel girders and a light scaffolding system. Once the slabs were set, the team transitioned to pouring the concrete deck and applying mastic asphalt. The final leg of construction saw the bridge fitted with railings, road and architectural lighting, and drainage.

The Danube Valley Bridge and this phase of the A26 opened to the public in November 2024, offering an innovative and elegant structure without detracting from the region’s greatest attraction, the river below.

The opening was celebrated in November. Photo © ASFINAG

-High-Caliber-Captures.jpg?height=200&t=1725895765&width=200)