Imagine fully demountable, prefabricated concrete floors that reduce emissions by two-thirds and are beautiful to boot. This is what Swiss company Vaulted claims to deliver with its Rippmann Floor System (RFS), named for the late Matthias Rippmann, a member of the Block Research Group (BRG) at ETH Zurich, Switzerland’s prestigious polytechnic university.

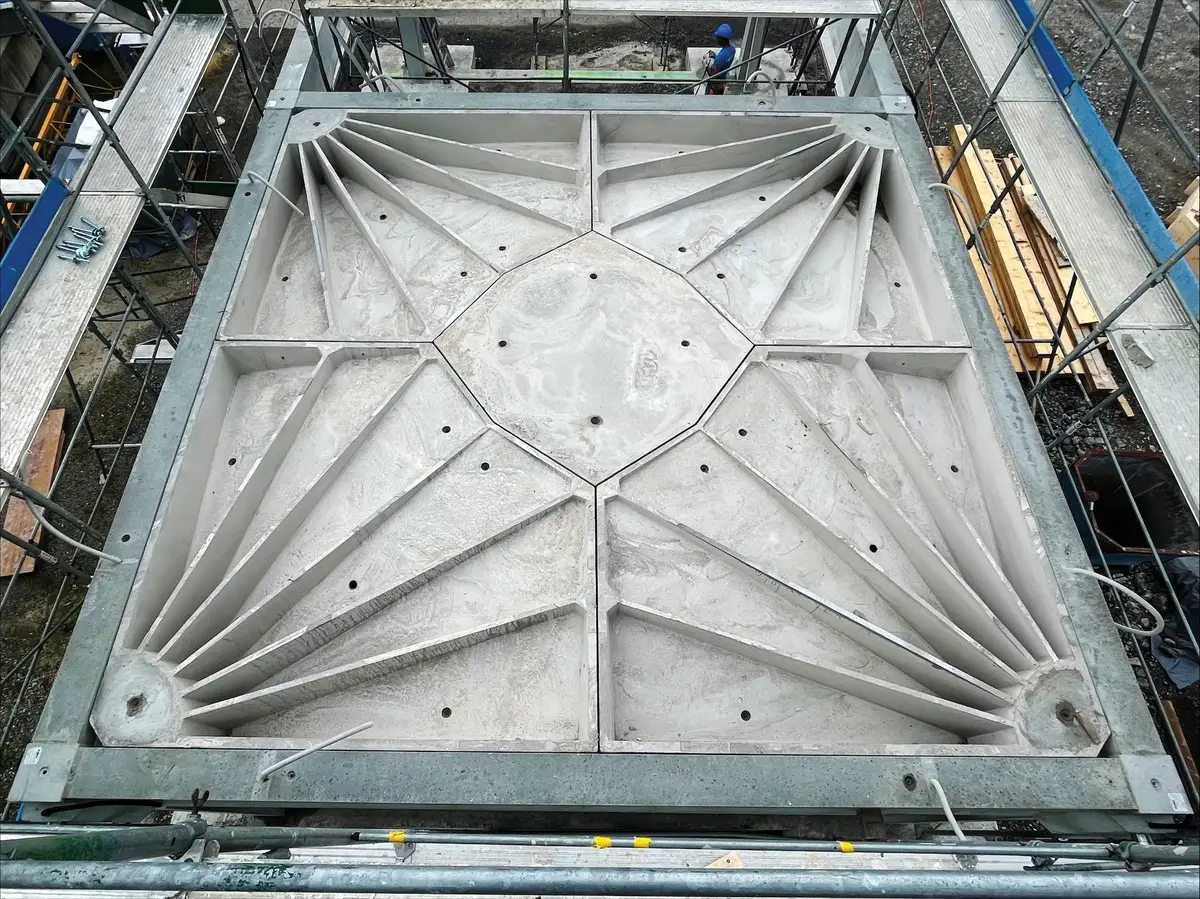

The RFS uses concrete only “where it wants to be in compression,” says the company. Unlike the Gothic technology on which they are based, Vaulted’s RFS shells are stiffened by ribs located on their hidden, upper surface, with the lines of force inscribed on their visible face underneath. As currently available, they come in two versions: double span (RFS-D) and single span (RFS-S). While the RFS-D modules fit together to form what resembles a classic quadripartite vault, which is to say curved in two directions and supported at the corners of its square perimeter, RFS-S is curved in just one direction, its components forming a barrel vault that must be supported along its two edges. This dual offer, says Francesco Ranaudo, Vaulted’s CEO, responds to RFS-D’s limited flexibility with respect to internal partitions, since running them through the middle of the vault is inelegant; with its narrower spans, RFS-S is better suited to housing, for example, which generally requires smaller rooms than offices. “We’re really going back to a tectonic appreciation of architecture,” comments Ranaudo.

Lines of force are inscribed on the underside of the panels. Photo © Philippe Block

The pieces resemble a quadripartite vault once assembled. Photo © Philippe Block

The average flat concrete floor slab, he continues, is around 10 inches thick, whereas the RFS shells measure only 2½ to 3 inches (which, by chance, is just the right amount for thermal insulation). The only reason the shells might get thicker is for fire protection, although tests have shown they will resist for at least an hour. If the vault’s perimeter dimensions increase, it will rise higher to cope with the reconfigured forces. “If necessary, we can make very shallow vaults,” clarifies Ranaudo, “but that means you’ll need either more mass or more steel reinforcement in whatever part of the structure is absorbing the lateral thrust.” Where the building structure is concerned, Vaulted offers an in-house design service for those unwilling to tackle the calculations. As for the concrete, “we can use any type we like,” indicates Ranaudo, “but we avoid the strongest ones, since they’re the most polluting and also pose fire-safety problems.” Vaulted is currently collaborating with Swiss construction giant Holcim, which is developing various low-carbon concretes.

In a few years, Vaulted hopes to offer a standardized range of products with detailed installation instructions, but for now the firm is offering “customized mass-production” solutions. Vaulted’s involvement begins at the concept-design phase, to make sure the shells conform to the building’s structural grid and to accommodate any irregularities. Mounting the RFS on-site requires no specialized workers or equipment.

Vaulted emerged from BRG founder Philippe Block’s Ph.D. research into assessing the performance of masonry vaults. “He wondered how you might use his analytical technique as a design tool,” recalls Ranaudo, “after which Matthias Rippmann took things a step further by developing the RhinoVAULT plug-in in 2012.” Over the following decade, BRG began to develop funicular-floor prototypes in concrete and, in 2021, tested the idea as a poured-in-place version at HiLo, part of a life-size experiment in low-carbon construction at Dübendorf, Switzerland. “After HiLo, I began researching the possibilities of prefabrication,” continues Ranaudo (also an architect and engineer, who joined BRG in 2018). In 2023, alongside Block and BRG codirector Tom Van Mele, he cofounded Vaulted as an ETH spinoff, and now works full-time for the company.

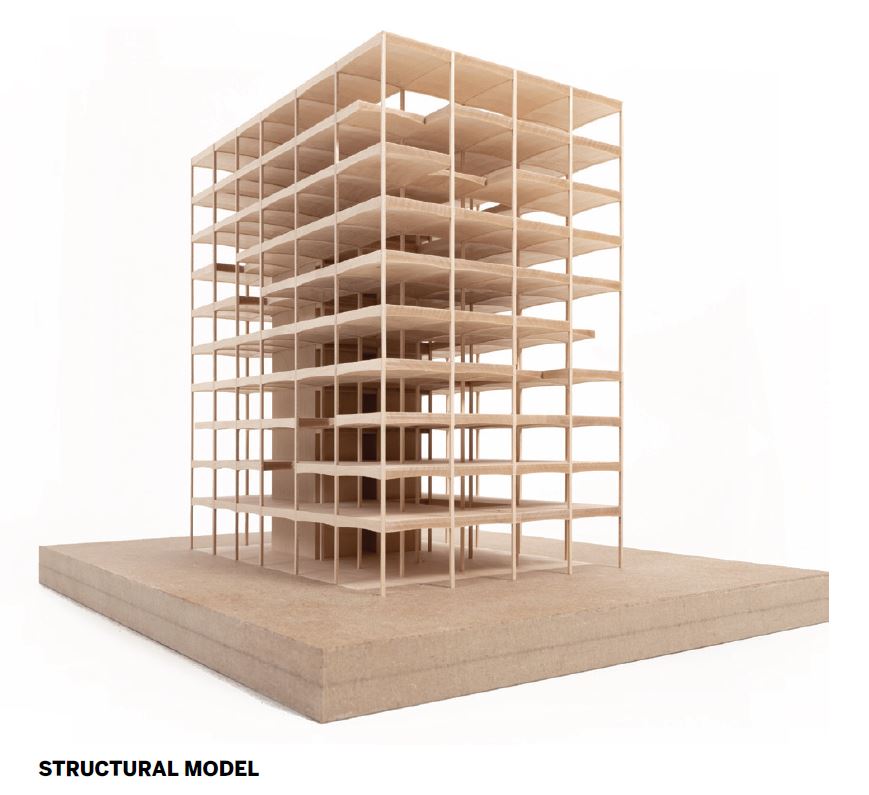

The first new building to complete using Vaulted’s RFS system will probably be CreaTower I in the Swiss city of Zug. Designed by Zurich-based architect Gigon Guyer, the 10-story office block is due in 2028. As partner Stefan Thommen explains, the decision to try out the technology arose from a design studio that cofounder Mike Guyer taught with Block at ETH. In Zug, the height restriction of 131 feet led Gigon Guyer to request shallower vaults than would be optimal, so as to squeeze in the tall floors requested by the client. Where the supporting structure was concerned, the architects designed a pre-tensed, prefabricated concrete frame engineered not only to absorb wind load and vault thrust, but also to ensure flexibility. “If you optimize, you remove redundancy, but you may also be removing the ability to accommodate a change in use,” explains Ranaudo. To future-proof, the capacity to handle different loads and situations must be anticipated—at CreaTower I, Vaulted had to demonstrate it could fill in double-height spaces with supplementary floor shells at a later date.

1

2

CreaTower I, in Switzerland, will be the first new building to use Vaulted’s technology (1). The interior will feature double-height spaces that could be filled in at a later date (2). Photos © Ponnie Images

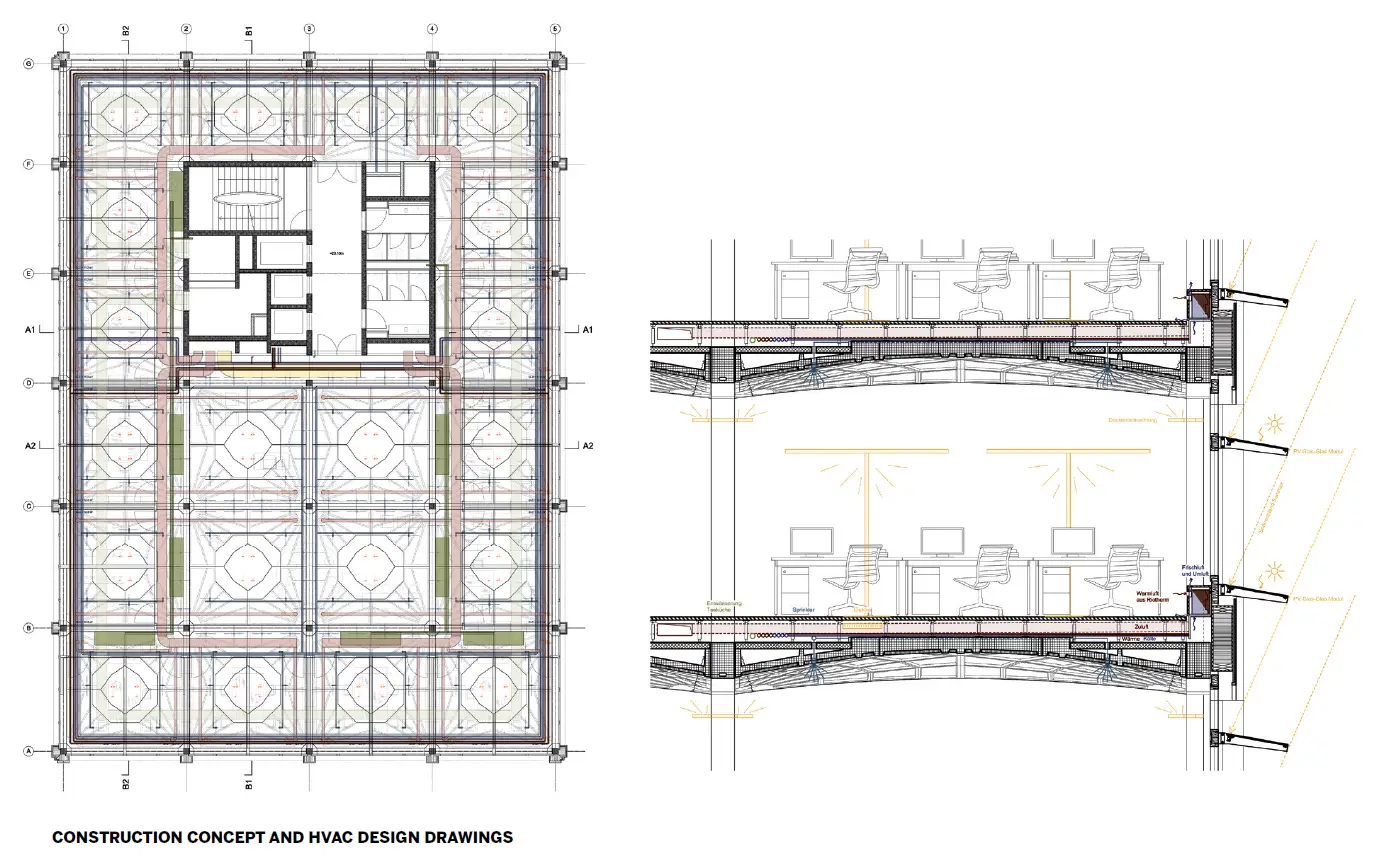

Gigon Guyer’s building will run HVAC and wiring under raised floors, although other solutions are possible—ducts could be dissimulated within the thicker parts of the vaults or hung beneath them, says Ranaudo. In Switzerland, the technology has run up against the country’s stringent acoustic regulations, which deem the RFS shells too thin: Gigon Guyer has added nonstructural concrete slabs nearly 4 inches thick, to meet requirements. In its current bespoke form, the RFS is also more expensive than classic floor slabs, despite the considerable savings in cement, aggregate, and steel. “If CO2 emissions were more strongly taxed, there would be a greater incentive to adopt it,” comments Thommen.

“We made a strategic decision to focus on Switzerland, since we know it so well, and to build our reputation here,” says Ranaudo. “But we’ve designed the floor to be compliant with codes in the E.U., the U.S., and everywhere else. Taking Vaulted further will essentially be a question of opportunity.”

Click graphic to enlarge

Click graphic to enlarge