Artificial intelligence continues to advance at a rapid pace, leading to calls to ensure that its capabilities and influence do not grow unchecked. In 2018, the Massachusetts Institute of Technology established the Stephen A. Schwarzman College of Computing (SCC) as part of a $1 billion commitment to address the “opportunities and challenges presented by the prevalence of computing and the rise of artificial intelligence.”

This investment included creating a home for the SCC. The project’s brief called for a “signature” building to house laboratories, classrooms, and offices on the northwest side of Vassar Street, then considered somewhat of a back side to the Cambridge campus. Surrounding its site was the sculptural, white limestone–clad Brain and Cognitive Sciences Building by the late Charles Correa with Goody Clancy; the expressive metal and brick volumes of the Ray and Maria Stata Center by Frank Gehry; and a collection of nondescript 1960s and ’70s concrete and masonry structures. To its rear were an active rail line and parking lots.

To counter the hodgepodge of architectural styles while celebrating the college’s mission to advance technology in a responsible, transparent way, Skidmore, Owings & Merrill successfully proposed a rectilinear building with twin wings with textured facades of large-format glass shingles. Canted in both plan and section, each glazed unit was intended to look “suspended in air, disconnected from the last one,” says SOM partner Colin Koop. “You’re not even sure if it’s a fully enclosed building.”

The SCC sits among a hodgepodge of architecture styes (above and top of page). Photo © Lucas Blair Simpson, click to enlarge.

Furthering the illusion, the shingles run past the building’s edges at its roofline and sides, creating a “great, transparent sail” that Koop says enhances the structure’s relatively modest stature—178,000 square feet over eight floors—and symbolizes the SCC’s “outsized importance to the future of the Institute.”

But, by designing a south-facing elevation with a 67 percent window-to-wall ratio, the team knew they had to deliver on energy performance in “legitimate. . . scientific and measurable ways,” says SOM technical design partner Carrie Moore. Furthermore, executing the composition of overlapping glass shingles would not prove straightforward.

Suffolk, the project’s general contractor, was brought on early in a design-assist capacity; it quickly determined the shingled facade would drive the construction’s critical path. As a result, SOM delivered the building-envelope package first, in 2020, before aspects of the project’s structure and interior were finalized. Permasteelisa North America won the contract and subcontracted the shingled facade to Gartner, a Permasteelisa Group member.

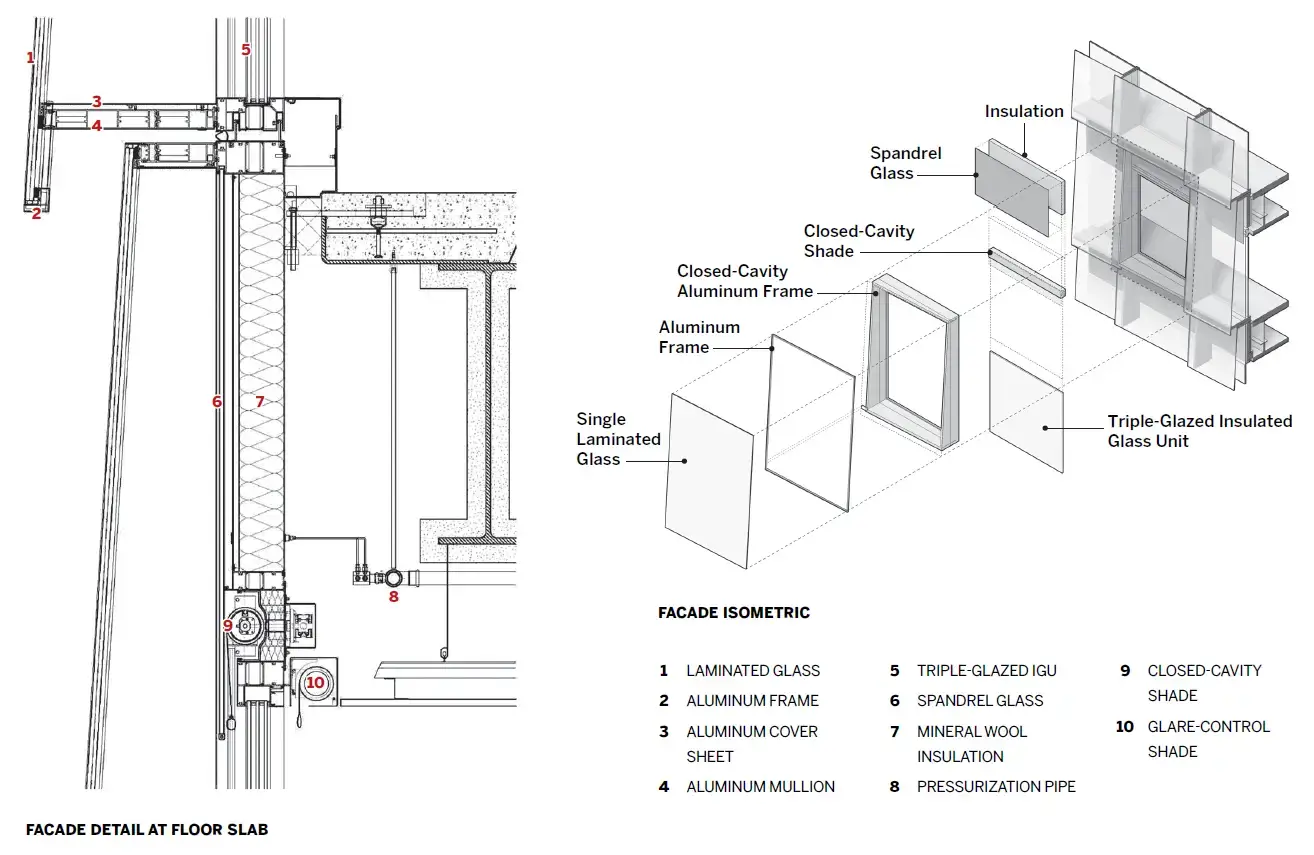

Working together, the project team developed a closed cavity facade (CCF) system in which each shingle would comprise a double-skin assembly with a hermetically sealed air plenum and integrated shading system. The CCF would reduce energy consumption by about 25 percent over a single-skin insulated-glass curtain wall, Moore says.

The symmetrical elevation comprises 140 glass shingles, each 14 feet tall and 10 feet wide. Of that total, 44 are “flybys” that continue beyond the building perimeter and integrate additional steel structural components and edge details.

The outermost skin of the CCF assembly is laminated glass heftier than is typical in anticipation of high wind loads and suction pressure. Set in an aluminum frame, the layer comprises two 10-millimeter-thick lites with a polyvinyl butyral interlayer. The outward-facing surface of the outer lite, surface #1, has a 20 percent solar-reflective coating, while surface #3 is fritted with a grid of gray dots for bird safety. The facade’s inside skin is a triple-glazed insulated unit comprising a 10-millimeter-thick lite and then two 8-millimeter lites; the latter two have a low-E coating on their respective outside surfaces (#3 and #5).

Between the inner and outer skins is the closed cavity, which ranges in depth from approximately 4 to 22 inches because it is trapezoidal in both section and plan. Filtered, dehumidified air is circulated in the cavity to prevent dust buildup and condensation.

Within each cavity, an automated roller shade tracks the sun’s position. On the interior, a manual shade allows occupants to reduce visual glare.

The combination of high-performance glazing and coatings maintains a relatively high visual light transmission (VLT) rating of 52 percent when the automated shades are up, and 4 percent when they are down. VLT designates the amount of visible light that can pass through a glazing unit, with 100 percent indicating complete transparency. The assembly’s solar-heat gain coefficient is 0.38 with the shade up and 0.10 with the shade down; this value indicates the fraction of solar radiation transmitted inside and can range from 0 (no transmittance) to 1.

The assembly’s U-value, which indicates its ability to transmit thermal energy, is 0.14 Btu/(h-ft2-°F); typical U-values for window assemblies range from 0.20 to upwards of 1, with a lower number being more desirable. “This is one of the highest-performing [glazed curtain] walls in the entire U.S.,” says Andrea Zani, sustainability and building-physics leader for Permasteelisa NA. He estimates that the building operational energy saved by the double-skin CCF will pay back its additional embodied energy over a single-skin system in 10 to 20 years. Moore notes that the SCC building was designed at a time when building performance was top of mind. “Today, we are all smarter around the dynamics of operational carbon versus embodied carbon, and balancing those things,” she says.

One benefit of the CCF is that the temperature of the interior-facing glass is close to the temperature of the room, in both the winter and summer, points out Zani. “You don’t feel that discomfort you sometimes have when you’re sitting close to a big glass facade.”

SCC students, who are known for working independently and among others, probably also appreciate the system’s acoustical properties. With a sound-transmission class rating of 0.48 to 0.50, the CCF effectively masks the bustle of Vassar Street, creating a serene environment inside the double-height lobby and ground-floor community spaces, which feature warm wood finishes and meticulous detailing.

Ground-floor community spaces feature wood finishes and meticulous detailing. Photo © SOM / Dave Burk

Strategically, SOM was more conservative in the building’s remaining elevations, regarding both budget and aesthetics. Considering the close building adjacencies to the west and east, and a potential campus expansion to the north, the architects designed a conventional double-glazed, unitized curtain wall system incorporating metal panels. On these facades vision glass is more restricted, with window-to-wall ratios ranging from 15 to 40 percent.

Beyond its envelope, the building incorporates sustainable strategies that include the reduction of potable water use by 40 percent and prioritization of Red List–free materials for the interiors. The project is targeting LEED Platinum certification.

The SCC has changed the tenor of Vassar Street on the MIT campus. “You can walk by that building at any time of day or night, and it’s full of people,” says Travis Wanat, MIT’s director of capital projects. The foot traffic and vibrancy inside the building, which spills out, both physically through the doors and visually through the facade, has “revitalized the public realm,” Koop says. The liveliness is “even greater than we had hoped for.”

Click details to enlarge

Credits

Architect:

Skidmore, Owings & Merrill — Colin Koop, design partner; Laura Ettelman, managing partner; Carrie Moore, technical design partner; Leonard Lopate, Julia Grabazs, associate principals; Lulu Li, Catharine Pyenson, associates; Edwin O’Brien, Bryan Kim, Jason Dufilho, senior designers; Eugene Ong, David Amdie, Boer Deng, intermediate designers; Trey Thomas, designer; Ivy Wang, architect; Charles Besjak, structural engineering principal; Georgi Petrov, senior associate principal, structural engineering; Selam Gebru, associate, structural engineering; Rowan Georges, senior associate principal, specifications writer

Engineers:

Skidmore, Owings & Merrill (structural); Arup (m/e/p, fire & life safety, sustainability); Nitsch Engineering (civil)

General Contractor:

Suffolk

Client:

Massachusetts Institute of Technology

Size:

178,000 square feet

Cost:

Withheld

Completion Date:

April 2024

Sources

Curtain Wall:

Permasteelisa North America/Gartner

CCF Roller Shades:

Warema with Verotex Fabric

Glass:

Saint-Gobain, Technical Glass Products

Exterior Glass Guardrails:

CRL

Entrances:

Blumcraft