Future Proofing Your Building: Where HVAC and Sustainability Come Together

Photo © Mitsubishi Electric Trane HVAC US

Introduction

Variable Refrigerant Flow (VRF) zoning systems solve many challenges associated with commercial construction and facility management.

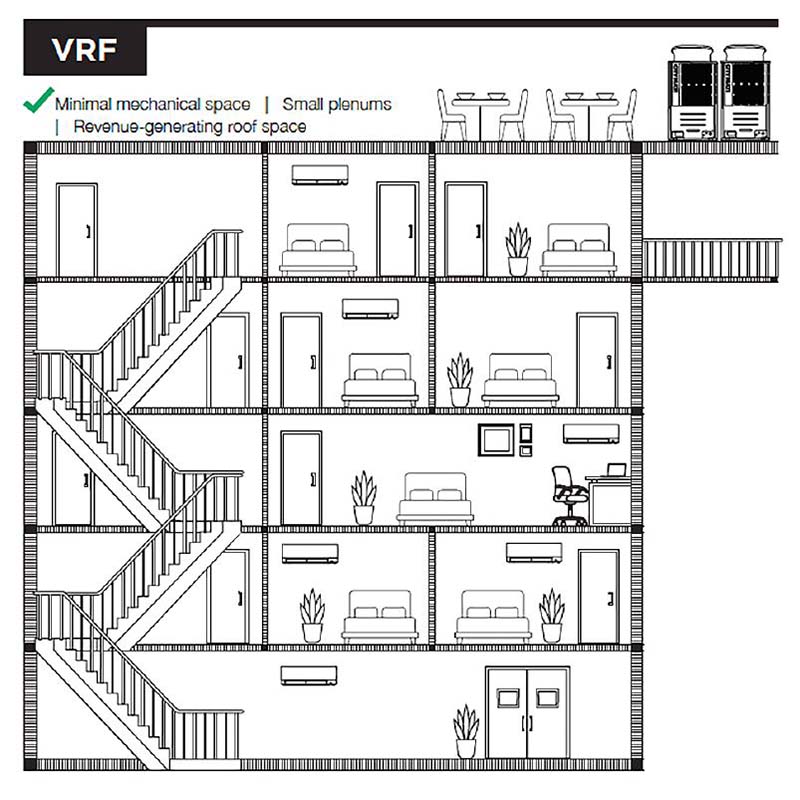

VRF systems pose a number of benefits, driving their growing popularity in the commercial building industry. They allow for the maintaining of set points specific to occupant usage and individual zone requirements to reduce the likelihood of hot and cold “trouble” spots. VRF systems are also more compact and require less ductwork than conventional equipment. Additionally, their smaller footprint means they require fewer alterations to building facades, making them ideal for owners and developers looking to maintain the integrity of historical buildings or create rooftop entertainment spaces. The low operating sound levels mean the equipment will not disturb guests as they enjoy rooftop or outdoor amenities.

VRF systems also offer benefits related to cost reduction or avoidance compared to conventional systems.

One of the most significant benefits of VRF zoning systems, however, is how they contribute to sustainable buildings by relying solely on electricity to deliver energy-efficient performance. This benefits cities, states and building owners looking to reduce carbon emissions and deal with rising energy costs. We’ll take a deeper dive into sustainability, strategic electrification and decarbonization later on, but first, let’s start with an overview.

Getting Started with VRF

VRF systems provide personalized heating and cooling to multiple zones in a building by cycling refrigerant between an outdoor unit (air-source or water-source) and indoor units in each zone via refrigerant lines. Indoor units are available in ductless or ducted styles to match the zone’s requirements or limitations.

Click graphics to enlarge

Image © Mitsubishi Electric Trane HVAC US

In moderate climates, HVAC contractors typically install VRF heat-pump systems. In hotels, office buildings and any facility where some zones will require heating while others require cooling, HVAC contractors will install a heat-recovery VRF system that uses a branch circuit (BC) controller to provide simultaneous heating and cooling.

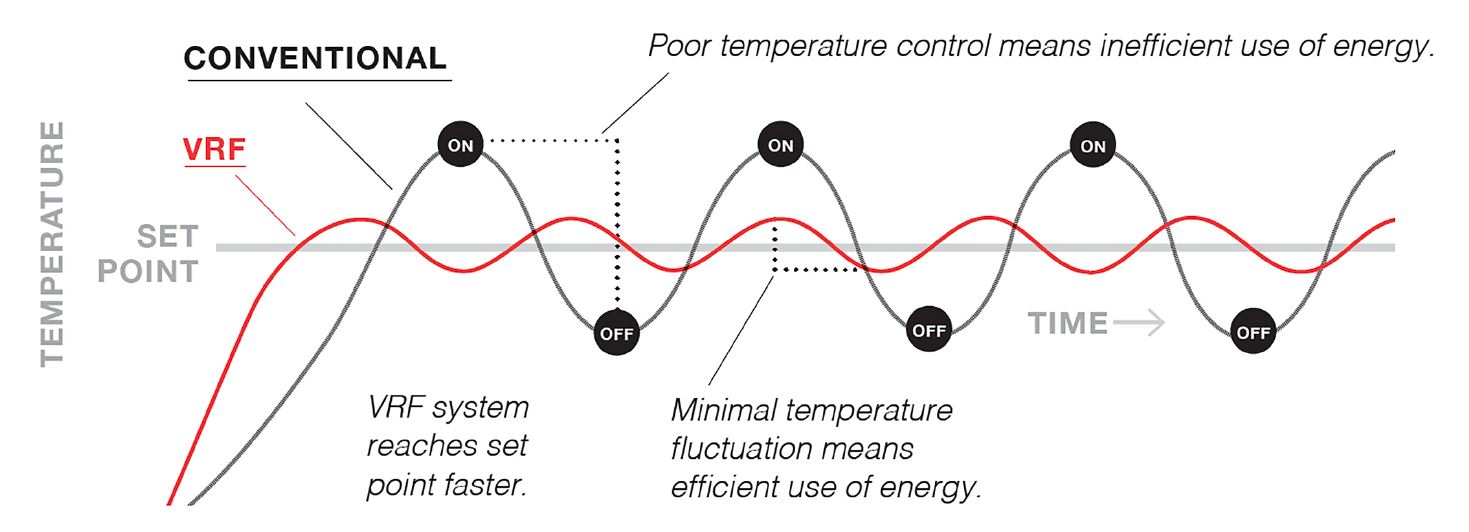

While sized to meet design temperatures, each VRF outdoor unit has an INVERTER-driven compressor enabling the system to vary capacity to match the current load, using only the precise amount of energy needed. The majority of operation is during partial-load conditions, saving money by reducing energy consumption by up to 40 percent compared to conventional, fixed-capacity systems. Variable capacity enables VRF systems to precisely maintain set points without the noisy and energy-intensive start/stop cycles of conventional systems.

Benefits of VRF systems include:

LOWER LOADS

The INVERTER-driven ability of a VRF system to match capacity with loads enables it to heat and cool a low-load building with less risk of short cycling than fixed-capacity equipment. The most high-performing buildings have efficient mechanical systems, as well as low heating and cooling loads achieved through continuous insulation and an airtight thermal envelope.

STREAMLINED MAINTENANCE

Once per quarter, clean coils, check electrical connections, check the refrigerant charge, inspect refrigerant lines and wash reusable filters, which last up to 10 years.

ELIMINATED COMPLEXITY

VRF systems reduce or eliminate requirements for belt changes, boiler analysis, chiller maintenance, cooling towers, filter replacements, pump seals, strainer cleaning, water treatment and 10-year overhauls.

COST AVOIDANCE

The first opportunities to reduce costs with VRF systems emerge during mechanical design. HVAC specifiers can help developers and building owners look beyond the mechanical bid to demonstrate how VRF systems allow them to avoid costs associated with alternatives such as PTACs and Variable Air Volume (VAV) systems. The complexities of HVAC systems dictate requirements that impact the developer’s first cost and total cost. For example, VRF systems allow developers to eliminate PTAC sleeves and limit wall penetrations and louver openings. VRF systems are modular, typically requiring less design time, and are also easier to install than conventional systems. These benefits contribute to a more efficient process and provide labor cost savings.

Images © Mitsubishi Electric Trane HVAC US

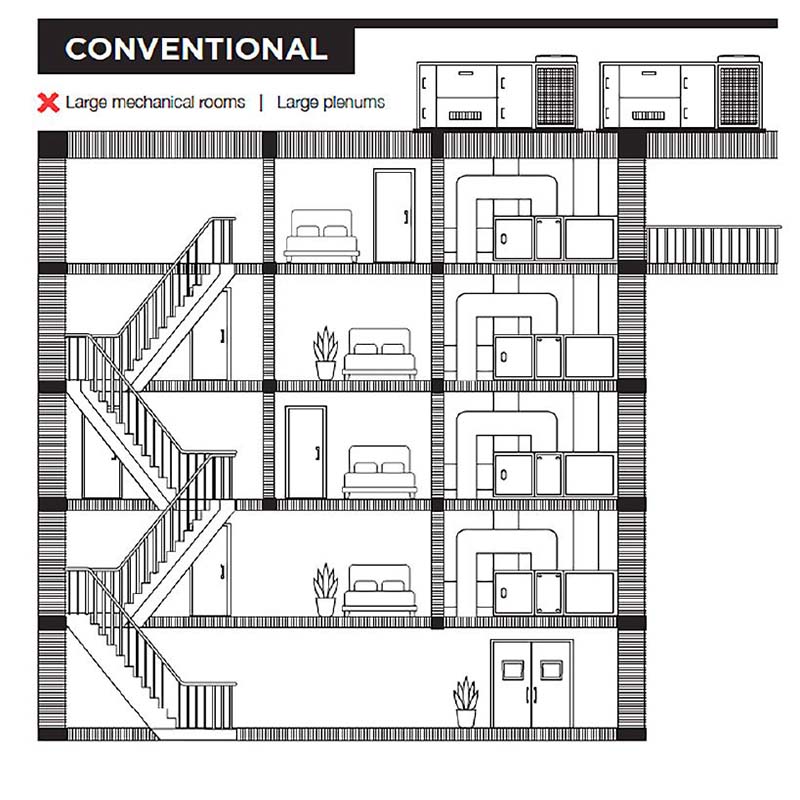

MAXIMIZED SPACE: SMALLER PLENUMS

While VAV systems require large duct runs to move conditioned air, VRF systems utilize small diameter piping to move conditioned refrigerant. This allows for smaller plenums with reduction of space between floors. Rooms appear more spacious and architects can demonstrate how to reduce construction costs by, for example, designing shorter buildings with the same amount of usable space. In some applications, smaller plenums will allow developers to increase usable space with additional floors. Taller spaces may also provide opportunities to add windows for increased natural lighting.

MINIMIZED MECHANICAL ROOMS

VRF equipment is compact compared to conventional HVAC units and is distributed rather than centralized. This reduces space requirements for mechanical rooms.

LESS MONEY SPENT ON STRUCTURAL SUPPORT

At an average weight of 70 pounds per ton for an outdoor unit, VRF equipment is up to 30 percent lighter than alternatives such as chilled water systems. This reduces requirements for structural steel and lintel beams.

DEFERRED COSTS UNTIL LEASES ARE SIGNED

The design flexibility of a VRF system’s modular components mean contractors can finish out a system floor-by-floor based on tenant needs. This allows developers to defer part of the installation costs until leases are signed.

ENERGY APPORTIONMENT AND EFFICIENCY

If the building owner bills tenants for energy consumption or needs to bill for usage in excess of projected consumption, energy-allocation controls applied with VRF systems provide the ability to track the energy usage of individual tenants. This solves the challenge of billing for energy consumption in facilities with multiple tenants. For office buildings where the projected energy usage and utility bills associated with each tenant are incorporated into the monthly rent, the energy efficiency of VRF systems creates opportunities to offer more competitive leases with minimal impact to profit. Energy allocation is ideal for multifamily, office and mixed-use buildings.

COMPETITIVE ADVANTAGES

Not all developers and building owners will immediately recognize the benefits of lower bills and overall reduced energy usage. If tenants are responsible for utility bills, some will look at the capital costs associated with VRF systems and decide there is little value in paying for an HVAC system known for its efficiency if systems with lower mechanical bids are available. Building owners will look past the mechanical bid once they comprehend the benefits of VRF systems over conventional systems. If they’re still unsure of the comparative advantages relative to first cost, they should consider the indirect benefits of certified sustainable buildings. According to recent studies, potential benefits include increased rental rates, higher occupancy rates and greater tenant satisfaction and retention.

Image © Mitsubishi Electric Trane HVAC US

Sustainability: For the Future

As touched on above, perhaps the most recognized benefit of VRF systems is their ability to contribute to the certification and marketability of high-performance buildings as sustainable. By selecting an all-electric system, you’re “future-proofing” your building, or in other words, preparing it to withstand challenges of tomorrow and beyond.

Why Decarbonize?

Carbon dioxide (CO2) absorbs and emits heat. As a naturally occurring greenhouse gas (GHG), CO2 helps Earth retain enough warmth to sustain life but too much can lead to excessive warming. For 800,000 years, before the Industrial Revolution and the widespread adoption of fossil fuel-burning technologies, the highest global average atmospheric amount of CO2 was 300 parts per million (ppm). As of 2018, the average amount was 407 ppm.

Fossil fuels are hydrocarbons consisting primarily of carbon and hydrogen. During combustion, the fuel’s carbon combines with oxygen. This makes CO2 an inevitable byproduct when a system burns fossil fuels to release energy used for work or heat. Unfortunately, the amount emitted by fossil-fuel burning technologies is on pace to increase atmospheric CO2 to volumes that will change our environment.

If our global energy demand grows and we continue using fossil fuels in the same way, the average amount of atmospheric CO2 will likely exceed 900 ppm by 2100. With increases in the amount of atmospheric CO2 the global temperature also increases. If the global temperature continues to increase at its current rate of 0.2° Celsius per decade, the climate will likely reach 1.5° C above pre-industrial levels between 2030 and 2052. At this temperature, the majority of climate scientists expect environmental changes to include rising sea levels, increased flooding, droughts, extreme heat, wildfires and new risks to human lives, infrastructure and biodiversity.

Decarbonization Via VRF

The reduction in CO2 emissions that comes with electric-powered VRF systems can help building owners keep their facilities attractive to tenants and prospective buyers.

VRF technology consolidates heating and cooling into one all-electric, multizone system for offices, hotels, schools, multifamily buildings, indoor agriculture facilities and practically any commercial application. Each zone is conditioned by its own indoor unit(s) and can have its own set point. Instead of burning fossil fuels, VRF heat pumps consist of an outdoor unit and up to 50 indoor units connected via refrigerant lines and a communications network. The system provides heating to zones by introducing ambient heat the outdoor unit extracts from the air or a nearby water source. During cooling, VRF heat pumps reverse this process as indoor units transfer heat from zones to the outdoor unit which then rejects the heat. Indoor units are available in ductless and ducted styles.

Public and private initiatives toward decarbonization coupled with the cost of energy are driving more stringent building codes and legislation. VRF systems are uniquely positioned to help building owners meet CO2 reduction goals while lowering utility costs. They’re designed for extended life cycles providing sustainable performance well into the future.

Case in Point

A primary school in New Hampshire has served its community for generations since its opening in 1952. Just as the school’s dedicated teachers continually refresh the curriculum for its students (ranging from prekindergarten through third grade), the community – led by the school staff, school board, parents and energy-minded community members – recognized the need to modernize the building for comfort and sustainability. A zoned VRF system would prove essential to this retrofit.

The school is housed within a brick masonry building. Prior to its modernization, the facility had no insulation. The walls had an R-value of 1, equivalent to a single pane of glass. The uninsulated slab of the building was above grade and resulted in cold floors during low ambient outdoor temperatures. The heat provided by the oil boilers provided minimal comfort.

Photos © Mitsubishi Electric Trane HVAC US

Additionally, on the south and east sides of the building, windows made up about 65 percent of the exterior envelope. This reflected 1950s-era design and was intended to maximize natural light but resulted in excess solar gain and heated masonry, which produced uncomfortable temperatures as high as 92 degrees well into November and December. These conditions challenged educators and their students.

A project team was formed by the school board to identify the best way to improve comfort at the school. VRF technology offered the unique ability to resolve comfort issues while simultaneously improving the school’s sustainability.

The VRF systems provides both heating and cooling to improve the educational environment at the school. Each zone, including each of the retrofitted 900-square-foot classrooms, is served by a wall-mounted indoor unit. The school’s multi-zone outdoor units use only the precise amount of energy needed to keep each zone at its setpoint, even in extreme cold outdoor ambient temperatures. This ability to modulate compressor performance means less electrical consumption, making the system a natural fit for how the school uses renewable energy.

Additionally, the school’s flat roof and daytime occupancy made it well-suited for a solar array to supplement the VRF system, further reduce reliance on fossil fuels and increase sustainability along with comfort.

Strategic Electrification: Electrify Everything

Strategic electrification aims to decarbonize Earth’s atmosphere, decrease pollution and reduce the costs of modern comfort and technology. Also known as “beneficial electrification,” this movement requires increased energy efficiency and end uses powered with electricity from cleaner grids and renewable sources. The movement will transform both the built environment and society’s modes of transportation. Despite the enormity and complexity of its challenges, strategic electrification can’t be dismissed as niche or a possibility of the far future. The movement’s happening now, driven by a mix of public and private entities on the local, state and national level proceeding along voluntary and mandatory paths.

Utilities, states, cities, agencies and nonprofits have published a steady stream of studies and reports on how strategic electrification is the best way to achieve aggressive carbon emission reduction goals. An example is New Jersey’s 2019 Energy Master Plan: Pathway to 2050. The report contains an analysis of decarbonization pathways performed by Evolved Energy Research and the Rocky Mountain Institute for the New Jersey Board of Public Utilities. The analysis found that fully electrifying vehicles and building systems was the most sensible pathway for New Jersey. Electric appliances and vehicles save money by using “roughly one-third the energy of gasoline vehicles or natural gas-fired water heaters and furnaces.” Electrified buildings give the state more options for energy generation and can lead to new quality jobs in the electricity and building industries, including HVAC.

New Jersey’s report recommends wider adoption of heat pumps in residential and commercial buildings and suggests the state provide incentives for installing all-electric building systems. This recommendation is consistent with other reports on decarbonization and electrification including The Action Plan to Accelerate Strategic Electrification in the Northeast and the Variable Refrigerant Flow (VRF) Market Strategies Report published by Northeast Energy Efficiency Partnerships (NEEP), one of six Regional Energy Efficiency Organizations (REEOs) funded in-part by the U.S. Department of Energy. In the latter report, NEEP referenced research conducted by the Vermont Energy Investment Corporation (VEIC) for the New York State Energy Research and Development Authority (NYSERDA) showing GHG emission reductions of up to 41 percent for older, large office buildings retrofit with VRF systems. The equipment included in the study demonstrated baseline VRF system performance and didn’t include the most highly efficient models currently on the market. Additional energy savings and reductions in GHG emissions are likely with newer equipment designed for cold-climate performance and higher integrated energy efficiency ratios (IEER) and coefficient of performance (COP) ratings. IEER measures part-load efficiency during cooling. COP measures the average amount of heat a system can deliver compared to the amount of electrical energy it consumes.

Navigant suggests energy efficiency spending in North America will grow to nearly $11 billion per year over the next decade. This includes rebates and financial incentives to encourage more sustainable buildings and the adoption of high-performance heat pumps and VRF systems. Along with federal standards and programs like ENERGY STAR®, tax credits and utility rebates will continue accelerating adoption of energy efficient alternates to fossil-burning systems.

POWER THERMAL END USES WITH RENEWABLE ENERGY

Decarbonization and strategic electrification will ultimately require buildings to power space heating and water heating with renewable energy. Renewable energy sources like wind and sunlight are non-dispatchable, meaning they can’t be turned on and off to meet power demands. Facilities still require heating and cooling at night, during cloudy days and when the wind isn’t blowing. Given the current limitations of onsite and utility-scale storage technologies, renewable sources don’t leave any room for electrical waste. By using the precise amount of electricity needed to maintain each zone’s set point, VRF systems mitigate the challenge of variable energy generation with INVERTER-driven variable capacity. This creates opportunities for well-insulated, high-performance buildings to power VRF systems with on-site renewable energy.

Image © Mitsubishi Electric Trane HVAC US

Solving Electrification Challenges with VRF Technology

Across the United States, a decline in coal-fired electricity reduced CO2 emissions by 2.1 percent in 2019. The last large coal-fired power plant in New England closed in May of 2017 and the last of New York’s coal plants are set to close by the end of 2020. But a decarbonized grid isn’t contingent on altruism. Renewable energy is now cost competitive with fossil-fuel-based generation for utility companies. As of 2019, utility-scale solar electricity costs $32 to $42 per megawatt hour (MWH) of electricity. Onshore wind costs between $28 and $54 per MWH. The cost of running existing coal plants is at an average of $33 per MWH while the cost of new coal plants ranges from $66 to $152 MWH. The United States produced almost five times as much renewable solar and wind energy in 2019 as it did in 2009. Wind and solar currently provide nearly 10 percent of the nation’s electricity.

Falling costs aren’t the only reason utilities are using renewable energy to strip electrons from their atoms. Mandates are responsible for about half of the growth in solar, wind and hydroelectric generation since 2000. 29 states and Washington, D.C. have set Renewable Portfolio Standards (RPS) that require a percentage of the electricity sold by utilities to come from renewable sources. State targets for this percentage currently range from 10 to 50 percent. Also, the Department of Energy intends for 25 percent of electricity in the U.S. to be drawn from renewable sources by 2025.

The energy efficiency and intelligence of VRF zoning systems may help utilities manage the challenges of peak loads, utility-scale storage and variable generation. This will be increasingly important as strategic electrification expands. Depending upon electrification adoption, the annual nationwide demand for electricity may increase by up to 3,700 terawatt hours (TWH) or 85 percent by 2050. Their performance benefits give utilities and states incentives to support wider adoption of VRF systems, but also provide a means to offer value to building owners through lower electricity bills, improved comfort, streamlined control and lower carbon footprints.

While seemingly complex, strategic electrification consists of three primary components: increase energy efficiency; power thermal end uses with renewable energy and decarbonize the electric grid. VRF heat pumps and heat-recovery systems help building owners, architects and engineers solve challenges for each component as well as emerging building codes, standards and legislation related to decarbonization.

Energy efficiency is a prerequisite for decarbonization. In regions with carbon-intensive power grids, using more efficient systems and appliances helps reduce energy consumption as a good first step toward lowering carbon footprints. VRF systems are up to 40 percent more energy-efficient than conventional, fixed-capacity HVAC equipment. Most of these savings occur during partial-load conditions as VRF systems continually adjust capacity and energy consumption to precisely match each zone’s load. Also, while gas-fired HVAC systems can’t exceed a COP of 1, VRF systems regularly achieve COPs of 3 and higher, meaning they can deliver much more heat than they consume in watts. Additionally, VRF systems require less ductwork than forced-air systems, further reducing energy consumed by fans.

Conclusion

Modern construction requirements, decarbonization efforts and rising energy costs position VRF technology as the primary heating and cooling method of the future. Total-installed-cost advantages plus the comfort and performance benefits should help developers and building owners choose VRF systems as the preferred HVAC technology of today. With more complete consideration for how VRF systems compare to conventional systems in terms of overall requirements and impact on a building, HVAC specifiers can easily explain the opportunities VRF systems create for creating competitive advantages and achieving sustainability goals.