Architectural components have the power to greatly improve the energy efficiency and overall performance of the building envelope. Among these components, roll-up metal doors are a staple in commercial and industrial applications, with new models offering increasingly higher levels of efficiency.

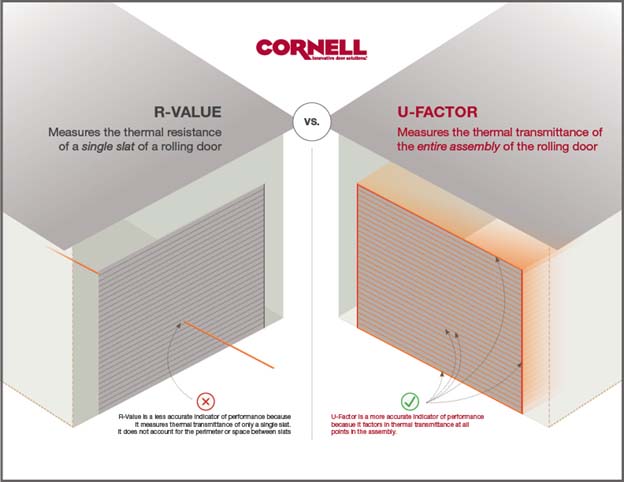

Traditionally, the industry has looked to R-value as the standard metric for evaluating thermal performance. For decades, it has been a go-to indicator of the insulating effectiveness of building materials. And while R-value is appropriate for static, uncomplicated architectural components like walls, it only tells part of the story of a roll-up door’s thermal efficiency.

The Role of U-Factor in Metal Rolling Doors

Using U-factor ratings for assessing the thermal efficiency of roll-up doors marks a step forward in the testing and metrics used by manufacturers, compared to reliance on R-value.

R-value measures the heat resistance of a single building material or static building component, indicating how well it resists heat flow. For construction professionals who want to increase the energy efficiency of a building and reduce heating and cooling loads with elements like insulation and windows, a high R-value is desirable. A higher number indicates the material or component provides greater resistance to heat flow, thus keeping heat inside during colder months and outside during warmer months.

U-factor measures the thermal conductivity, or the heat transfer rate, of the entire door assembly, capturing how quickly heat moves through the door under a specific set of conditions. When roll-up door manufacturers test their products for U-factor, they test the complete door assembly to measure how all of the door’s materials and components perform together. A lower number indicates the assembly has a slower rate of heat transfer; therefore, a low U-factor is desirable.

U-factor is a more accurate measure of thermal performance for a complex, moving structure like a roll-up door. R-value still plays a part by measuring the heat resistance of a single material or static component, but U-factor delivers a more comprehensive metric that speaks to the entire door assembly and its dynamic function.

The U-Factor Range

U-factor ratings for roll-up doors vary widely depending on the door’s component materials, the presence and type of insulation, and the door's engineering and design. It's important to note that the optimal U-factor for a roll-up door will vary, depending on the specific application of the door and its geographic location. While energy efficiency is a goal in every climate, the benefits of a low U-factor rating are greatest where temperatures tend toward the extremes. As a general guideline, a roll-up door with a U-factor rating below 0.85 is considered excellent.

Not all roll-up door manufacturers include U-factor ratings in their product specifications. Manufacturers that do – like Cornell – make it easier to specify their doors and accurately predict their thermal performance. They also contribute to the building industry’s broader goals of improving energy efficiency and sustainability.

Cornell Thermiser Max® - Low U Insulated Rolling Door Exemplifies U-Factor Trend

When Cornell introduced its Thermiser Max® Insulated Rolling Door in 2013, it became the most energy-efficient rolling door available on the market and one of the few products using U-factor in its specs. The Thermiser Max lists a U-factor rating of 0.82 Btu/h·ft²·°F.

While the Themiser Max raised the bar for thermal performance, Cornell is pushing performance even higher with the introduction of the next model in the series – Thermiser Max – Low U roll-up door. This new door represents Cornell’s highest efficiency door to date. The Low U model is scheduled to hit the market in summer 2024, and it will deliver a U-factor of 0.53 Btu/h·ft²·°F.

To lower the U-factor for this new model, Cornell product engineers focused on the amount of heat transfer that occurs in the door curtain at the joints between the individual door slats. Adding a thermal break with lower thermal conductivity at these points helped reduce heat transfer throughout the door curtain.

Adding U-Factor Benefits All Building Professionals

Regardless of one’s role in the design and construction process, having a metric that offers a more holistic measure of thermal performance leads to better outcomes. The adoption of U-factor benefits professionals in many key roles:

- Architects who are challenged with designing energy-efficient buildings can search for high-performance doors by looking for low U-factors. The more precise measure provided by a U-factor offers architects greater control over the indoor comfort and energy consumption of their designs, and it can help them earn credits toward LEED Certification.

- Engineers can apply more precise U-factor ratings when calculating a building’s energy efficiency and measuring the heating and cooling loads that affect a building’s operating costs. Choosing a roll-up door with a low U-factor rating to complement the efficiency of HVAC components and the larger building envelope is key to designing for sustainability.

- Specifiers and contractors can use U-factor ratings to ensure that they are adhering to energy codes. A rolling door with a low U-factor can contribute to lowering a project’s overall energy budget by helping to reduce heating and cooling costs.

Opening the Door to Greater Efficiency

Understanding U-factor and R-value is crucial for building and construction professionals designing with and specifying roll-up doors. By selecting doors with the best U-factor for their applications, building professionals can more tightly control the energy efficiency and indoor comfort of their projects — and that’s a door everyone wants to open.

Visit the Cornell website to learn more about the importance of U-factor and the soon-to-be-released Thermiser Max – Low U door.

By Heather Bender, Director of Commercial Product Marketing, Clopay Corporation